baghouse design calculations

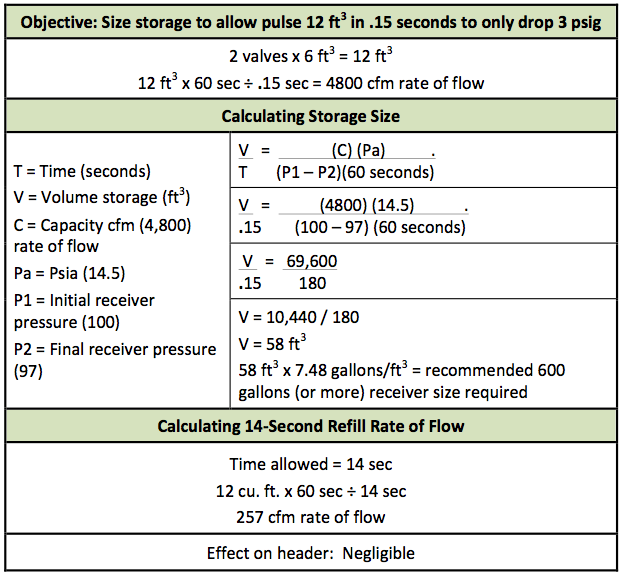

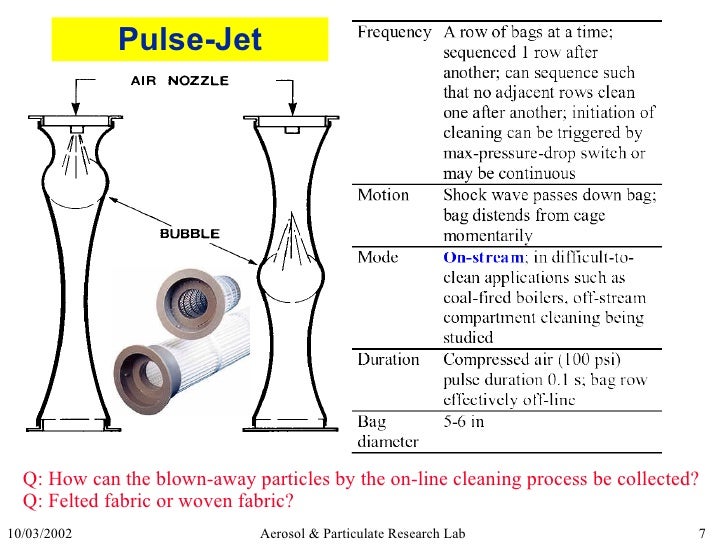

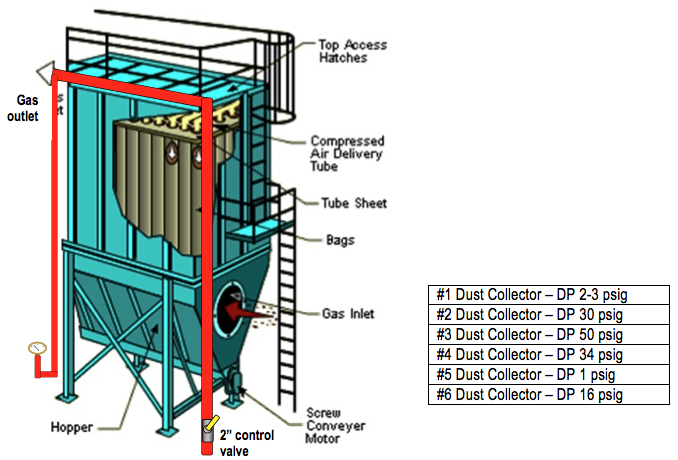

Bag Filter Calculation: Sizing Your System for PerformanceJun 5, 2019 To work properly, system designers need to perform a stock filter calculation. So how do you calculate the relationship between the air and the body of your bag filters? Some websites offer simple formulas to estimate the correct relationship between air and body. However, a good designer of the system knows that every application and every material is a little different. Systems designers also make a calculation of compressed air requirements for bag filters. Because without proper cleaning, the bags are covered with dust that eliminates the air-to-body ratio calculated. Therefore, getting these two correct calculations ensures that your bag works with all the efficiency. How to calculate the relationship between air and heat in stock filters A relationship between air and body compares the amount of air passing through a square foot of filter area. If you know the total CFM of the system and know the amount of filter area you have, you can calculate this relationship. For example, if you have 10,000 CFM through your collector and 5,000 square feet of filter area, your relationship is 10,000:5,000. But it's much easier to turn this into a 2:1 relationship. The relationship between air and body can be anything from 1:1 to 3.5:1. What is the difference in the calculation of the bag filter? Often, it is the type of dust that the system collects. Different types of material will change the way you calculate the relationship between air and body in filter bags. Most companies that design bags know the general area of the cloth of their filter bags. You can also calculate the filter bag because the filter bags are round. If you know the diameter of the bag, multiply this diameter in 3.14 to obtain the circumference. (Back to High School Maths and .)Therefore, the circumference of the bags (bag diameter x 3.14) multiplied by the length of the bag will give you an approximate bag surface. There are 144 inches square on a square foot. As the diameter of the bag will be measured in inches, the surface of the bag must also be measured in inches. Use this surface in the air-cloth ratio. Ask the manufacturer first You may never need to know how to make these calculations. Fortunately, many filter bag manufacturers know the general surface of their bags. In addition, a system designer usually knows the surface of the bags that need to go on a collector. What you need to know is why the relationship between surface and air matters. Consequently, an incorrect calculation of the stock filter design can result in a collector with a relationship that causes serious problems. Importance of correct calculations of the relationship between air and heat The correct relationship between air and body determines the efficiency and useful life of your filters. Above all, buying and replacing filters can be the most expensive and consumed part of maintaining the powder collector. The correct calculation of the bag filter extends the useful life of your filters and keeps them working efficiently. Do not have enough cloth for air in your system results in low filter life and damaged or overloaded filters. The different materials will require different air to body ratios. Different applications also require changes in the relationship between air and surface. An ambient system usually filters the air with a low global amount of particles. Instead, a source capture in the plasma court collects much more material. Wood, fiberglass and other materials affect filters differently. Therefore, you should consult with someone who has experience in relationship calculations between air and body for your type of material. Compressed air requirement calculation for bag filters Even if a system has the correct relationship between the air and the body, it still needs to clean the filters properly. For example, some bags are cleaned with airflow from a fan. The fan size will be part of the overall system design. Other bags use compressed air pulses to clean filters. For this, it is important to calculate the requirements of compressed air. The compressed air requirement for bag filters determines how long the bags will last and how efficient they will be. Some compressed air cleaning systems are operated by the timer. This means that compressed air pulses clean the bag filters at a time designed. Dust collectors can also have differential pressure control. In this case, an increase in differential pressure activates a sensor to activate a pulse. The compressed air only presses when the filters need it. This means that the compressed air requirement for the bag is lower. The size of the pipes and valves used can also affect the compressed air. A bag must be operated with the bag filters, valves and other equipment that come with the system, or an appropriate replacement of the manufacturer. The valves and other parts of the compressed air system can develop leaks and waste compressed air. As a result, there will be less efficient pulse. Therefore, systems must be regularly reviewed for any leak or failure valve. The calculation of the compressed air requirement for bag filters is only accurate if the entire system works as it is designed. Read more about bag filters . You also like it. Improve the health, safety and quality of life of people by building the best collectors of dust and smoke on earth" © 2021 • Site by Want to know more about our products? Program a virtual demonstration today!

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

PULSE JET BAG FILTER DESIGN - PULSE JET BAG FILTER DESIGN Flow gas rate Temperture Concentration of the dust in gases Average diameter of the particle | Course Hero

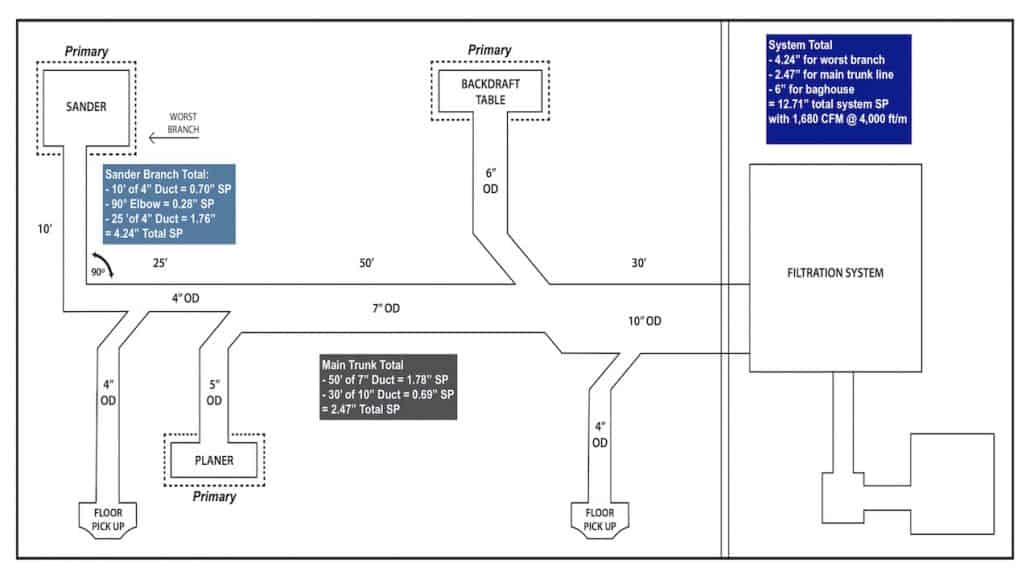

Design Process for Your Baghouse Dust Collection System (Part 3 of Design Guide) – Baghouse.com

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

Bag Filter Design Calculation Xls - DesaignHandbags

Designing and Sizing Baghouse Dust Collection Systems

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

The Four Key Baghouse System Design Variables (Part 2 of Design Guide) – Baghouse.com

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Maximizing Dust Collection System Efficiency | Compressed Air Best Practices

Pulse Jet Solenoid Valve - How They Work | Tameson

Baghouse Air to Cloth Ratio - Overview - YouTube

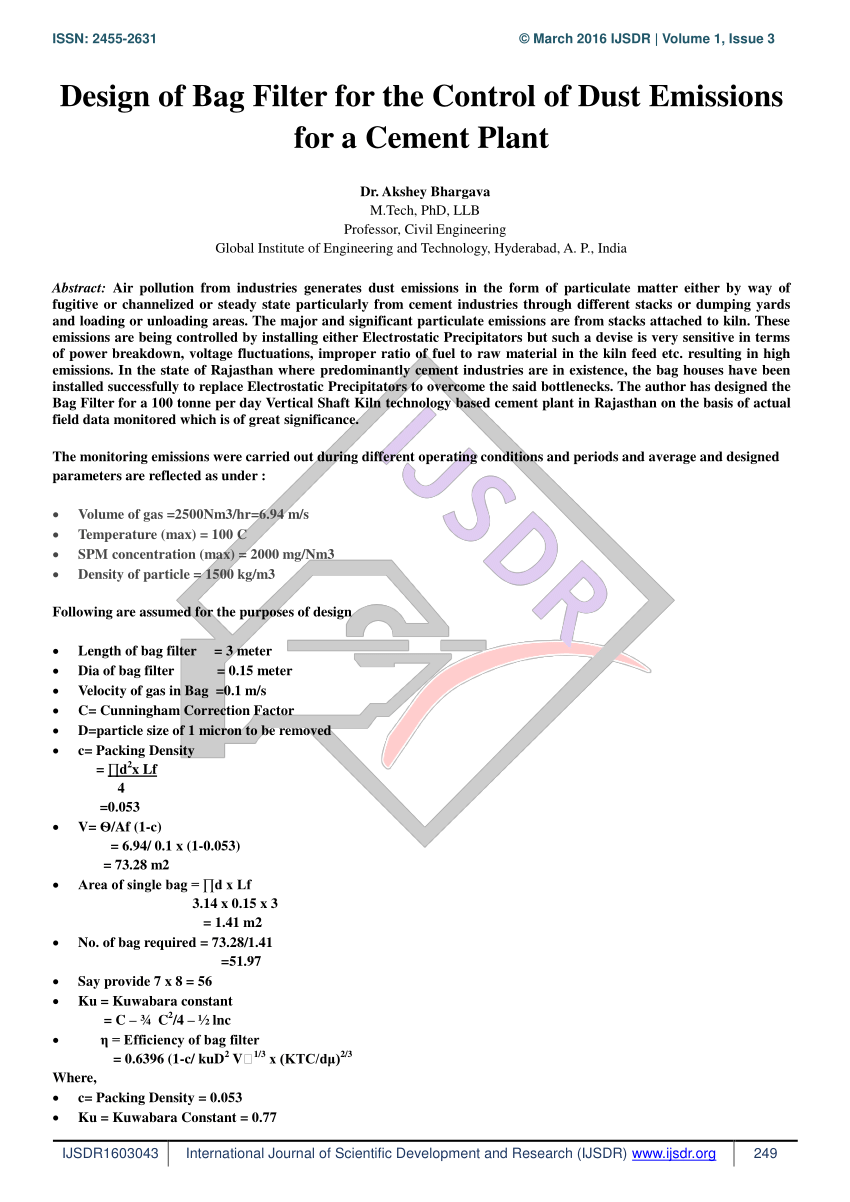

DESIGN OF PLEATED BAG FILTER SYSTEM FOR PARTICULATE EMISSION CONTROL IN CEMENT INDUSTRY

Bag Filter Design Calculations | Equipment | Nature

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Enviroflo Engineering - Enviroflo Engineering Pulse Jet Bag Filter

Enviroflo Engineering - Enviroflo Engineering Pulse Jet Bag Filter

.jpg)

System and Ducting Design | Scientific Dust Collectors

Bag Filter Calculation: Sizing Your System for Performance

Evaluation of the can velocity effect on a bag filter - ScienceDirect

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Air blow pipe design for bag filter house, Dust bag filter house, dust collector, dust filter bag house, pulse jet bag filter housing, clean system of bag house, problem of dust collector,

Bag Filter Design | Manufactured Goods | Gases

5.8. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in th

Baghouse Filters & Scrubbers - ppt video online download

Filters for pneumatic conveying - Dedusting after pneumatic transport

Baghouse - Wikipedia

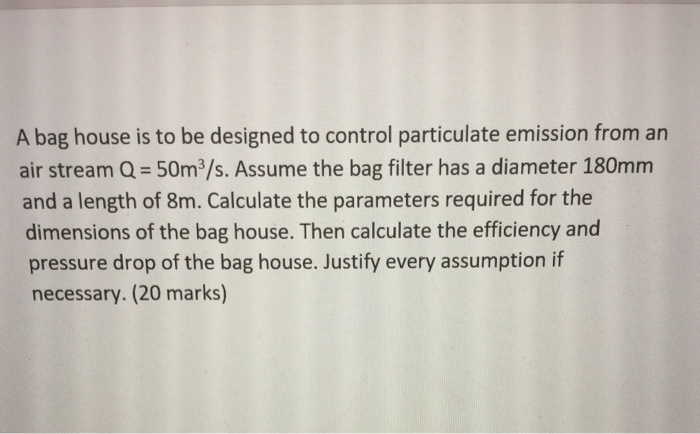

Solved: A Bag House Is To Be Designed To Control Particula... | Chegg.com

Pulse Jet Bag Filter Design Calculation - DesaignHandbags

Neundorfer | Optimizing the Performance of Air Pollution Control Equipment

Industrial Baghouse Filter Bags for the Cement Industry | Gore

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

applied sciences

MAXIMIZE EFFICIENCY. MINIMIZE PROBLEMS.

Compressed Air Requirement for a Bagfilter

Baghouses and Baghouse Filters Selection Guide | Engineering360

Dust Collector Design Sample Calculation

Bag Filter Calculation: Sizing Your System for Performance

Baghouse Basics

Posting Komentar untuk "baghouse design calculations"